History of the Avery Company

By J. P. Carroll

Caterpillar Tractor Company

We engineers are primarily concerned with current and future problems; however, an occasional look at history helps us to do a better job of evaluating the present and planning for the future. I think the Avery story will be interesting to you because the Avery Co. was Peoria's largest manufacturing industry in the early '20s and its demise presents a case for engineering, research and training programs.

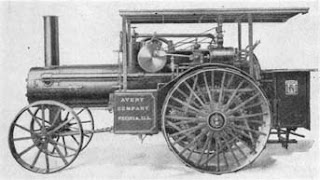

The idea responsible for the founding of the Avery enterprise had its inception in the Andersonville Confederate Prison when a captive Union soldier named R. H. Avery spent his prison time sketching a design for a corn planter in the sand. At the close of the war Mr. Avery returned to his farm home in Kansas and by 1874 he had a full size working model of his corn planter built. The original planter is now in the Edison Institute Museum at Ford's Greenfield Village in Dearborn, Michigan. In 1877 R. H. Avery and his brother C. M. Avery established a company bearing their names, in Galesburg, Illinois. R. H. had the inventive ability and C. M. excelled in the business end of the enterprise. They engaged in the manufacture of corn planters, stalk cutters and cultivators. Success was immediately theirs as their products met with wide acceptance among the farmers in the area. Because of better shipping facilities in Peoria, Illinois, the company purchased ten acres of land east of the intersection of North Adams and North Jefferson Streets. In 1882 they erected the three story square building which still stands, currently being used by R. G. LeTourneau, Inc. for offices. In 1883 the company name was changed to the Avery Planter Co. By 1891 they began the manufacture of steam traction engines and grain threshers. The first steam engines had top mounted engines and were used for both drawbar and belt work. The yellow wood threshers were known to the trade as the Yellow Fellow and were a big part of the company's business for over thirty years. Numerous Avery inventions were incorporated in their machines. R. H. Avery died in 1892 and his brother C. M. Avery ascended to the presidency. J. B. Bartholomew, a relative, was made vice-president. He was an outstanding figure in the company with inventive ability as well as business acumen. He was destined to lead the company to become Peoria's largest manufacturing industry. At the age of fourteen he invented a grain weigher for threshing machines. A major invention was the J. B. wind stacker for threshers, and, during his career, three large volumes of letters patents on farm implements were issued to him. At the turn of the century a company reorganization was effected with capitalization at $1,000,000 and the name was changed to the Avery Manufacturing Co. In 1902 a cemetery just north of the plant was purchased for future expansion. The Hannah Wagon Co. plant just back of their plant was purchased the same year and a number of branch houses were established in the principal mid-western cities. Expansion was under way, business was good and the products were accepted in the field. David McCullough, in his "history of Peoria" published in 1902, commented upon the Avery Manufacturing Co. in a chapter on Peoria industries. "The Avery Manufacturing Co. is a rapidly increasing business managed by young and progressive men. If the history of the manufacturing industries of Peoria shall be written fifty years hence, it is safe to say that the volume of business at present conducted by this concern, vast as it now is, will appear small in comparison with what it is destined to become as the result of growth and development of another fifty years." It might be interesting at this point to mention a few contemporary highlights of the period. In the year 1903 the Wright Brothers made their first successful flight and the Ford Motor Co. was formed. In 1904 the Society of Automotive Engineers was organized, the first Vanderbilt Cup Race was held, the first Maxwell, Reo, Stoddard-Dayton and Studebaker automobiles were built, the Colean Manufacturing Co. was manufacturing farm implements and steam traction engines in East Peoria, and the first track-type tractor was built by the Holt Manufacturing Co. of Stockton, California. C. M. Avery died in 1905 and J. B. Bartholomew became president. Sons of the Avery's held minor executive positions, but from then on the business was under the absolute control of J. B. as he was known to everyone, even in printed advertising literature. The capital stock was increased to $2,500,000 in 1907 and the name was changed to the Avery Co. By then their products were being distributed worldwide. Another point of parallel history of interest to Peoria occurred in 1909 when the Holt Manufacturing Co. purchased the bankrupt Colean Manufacturing Co. plant and established their eastern manufacturing branch in East Peoria. The three story Avery office building was built on the west side of the Adams and Jefferson intersection in 1910 and the following year, after moving the cemetery, the large buildings now occupied by R. G. LeTourneau, Inc. were erected. Further product development brought the 1912 locomotive style double under mounted steam traction engine on the market. One of these is also in the Edison Institute Museum. The internal combustion engine was now challenging steam power for tractors, so the first of a line of gasoline powered tractors appeared in 1912 along with a line of two, three, and five ton trucks. Later some of the trucks were of the cab-over-engine design. The gasoline tractor engines were of the opposed cylinder design in both two and four cylinder models. The crankshaft was set transversely on the chassis permitting a straight spur gear type of transmission to the drive wheels.

The plant of the Avery Company covers a total of twenty-seven and five-hundredths acres and the main factory building, together with the various warehouses, have a total floor space of six and a half acres. The various departments of the factory are united by an improved type of trolley system of the company's manufacture which greatly facilitates the rapid handling of both finished and unfinished goods at a minimum of expense. That harmonious and notable relations exist between the company and its employees is indicated by the fact that labor troubles are unknown in their factory. The company manufactures steam and gasoline traction engines, self-lift plows, traction steam shovels, traction hauling wagons, threshing machinery and all its various attachments, mounted steel water tanks, farm wagons, corn planters, riding and walking cultivators, single "and double row stalk cutters and gasoline tracts — both farm and city. Their output is sent to all parts of the country and into foreign lands as well. They have branch houses located at Omaha, Des Moines, Kansas City, Minneapolis, St. Louis, Indianapolis, Grand Forks and Fargo, North Dakota, and Aberdeen, South Dakota. They have a large traveling force upon the road and their Canadian trade is handled from Winnipeg. Their foreign shipments go to Mexico, Argentine Republic, Brazil, Russia. Austria-Hungary, the Philippines, Portugal, China, Sweden, Cuba and Egypt. The foreign trade gives an outlet for much machinery at a time when the shipping season for the home trade is lightest. The officials of the company work together in the utmost harmony and their relation is one of close social as well as business interests. From Rice, James Montgomery. "Peoria City and County, Illinois: A Record of Settlement, Organization, Progress and Achievement," S.J. Clarke Publishing Company, 1912

The old Kingman Plow Co. plant a mile up the track was acquired for use as a foundry in 1916 and became Avery Co. plant No. 2. In 1917 the Davis Manufacturing Co. engine plant in Milwaukee, Wisconsin was purchased, becoming Avery Co. Plant No. 3. They were then prepared to build all of their own engines. The Glide automobile plant in Peoria Heights, Illinois was a side enterprise of J. B. Bartholomew's. He manufactured the Glide automobile for several years and in 1920 decided to bring the plant into the Avery Co. fold as plant No. 4 for the manufacture of trucks. With four plants comprising the Avery Co. and an employment of four thousand people, it appeared that David McCullough's prophecy was well on the way towards realization. Times were changing, however, as new developments were given impetus by World War I and competition was becoming a greater challenge in manufacturing industries. In the earlier years new inventions could be incorporated into machines for production as saleable products without any appreciable amount of engineering and development work. The time was now approaching when products had to be built better in order to compete for the customers dollar and to stay sold. An inventor with a few draftsmen could not accomplish this task alone; it required a program of engineering, research and training of young men to execute the program. The company realized that competition and product obsolescence were challenging their products. Two major developments in the far West were beginning to be felt in the Mid-Western area. The track type tractor and the combine-harvester were challenging the large steel tire wheel tractor and the stationary threshing machine. Mr. Bartholomew was quite capable of conceiving new and advanced ideas for products to create new markets. Here are some of the later developments. In 1917 the small motor cultivator appeared featuring a friction drive transmission with infinitely variable speeds. Later when the power was increased with the use of a six cylinder engine the friction drive was not adequate and a conventional clutch and sliding gear transmission was adopted. They built as high as fifteen hundred units a year. Here was a machine that the farmers were eager to own, but lack of proper engineering follow up in the field left these machines in need of de-bugging and then popularity was retarded as a result. A blade attachment was made for the motor cultivator and it was sold under the trade name of Road Razer. This one-unit grader idea was later carried further with the development of a larger machine permitting the blade to be placed between the axles. The blade assembly was mounted on a ball bearing slide rail which permitted quick side shifting of the blade. The "Track runner" was the only attempt at entering the track-type tractor field. The track operated on loose rollers in a continuous channel and the idea was abandoned after a number of unsuccessful applications. You can't blame them for trying for, with our free enterprise system we have the right to fail as well as the right to make a profit. Their first all steel thresher model was not placed into production as considerable engineering was required to make it commercially practical. That task was left for the successor company. The Avery Co. reached its key day in 1920 but clouds were appearing on the horizon. The agricultural depression of 1921 gave the company a jolt, and the missing segment in the arch of its organization, engineering, research and training, was making itself felt. The bubble burst in 1923 followed by bankruptcy and receivership in early 1924. One year later J. B. Bartholomew died, and 1925 was also the year that the Holt Manufacturing Co. of Stockton, California and Peoria, Illinois and the C. L. Best Co. of San Leandro, California merged to form the Caterpillar Tractor Co. Although popular opinion blamed over expansion for the failure of Peoria's largest manufacturing industry, I believe that it was a case for engineering, research and training programs. I believe this because concentration upon any one of J. B.'s latter day ideas would have assured success. Another company began mass production of the row crop type of tractor, very similar to J.B.'s motor cultivator, the same year the Avery Co. went bankrupt. Other companies were destined to develop and produce the one-unit type of motor grader. The Avery story would not be complete without telling you about the successor company which was organized in late 1925 as the Avery Power Machinery Co. A group of men, who had done a lot of thinking down stairs in the old company, joined, with the backing of several local business men and bankers, to organize the new company on a considerably smaller scale utilizing the major portion of the old plant No. 1. All of the other plants and parts of plant No. 1 were disposed of during the receivership. This new group of men decided to start without the engineering and experimental departments and to delegate proper authority to the various departments throughout the organization. They concentrated upon a line of advanced design steel threshers and combines and they hired two old time inventor-thresher men as consultants to the engineering department. Here is a statement of policy by the Avery Power Machinery Co. officers. "Every Avery owner must be a satisfied customer".

There are four bed rock principles which we believe in and are building upon:

1. Higher quality and simpler machines.

2. Back every machine with real service.

3. Always give a square deal.

4. A friendly spirit.

On the four bed rock principles we have built the four foundation walls:

1. A belief in concentrated energy.

2. A love for truth

3. A belief in first hand knowledge.

4. A belief in united effort.

We have laid these four corner stones:

1. Strong financing.

2. Advanced engineering.

3. Efficient manufacturing.

4. Economical distribution.

This was indeed a reaction to the policies of the predecessor company. History was their teacher. This fine group of men did go forward with their avowed policies to develop and manufacture an advanced line of all-steel anti-friction bearing threshers and combine harvesters. They continued to manufacture the Power Road Maintainer and parts for all of the previous machines. Their new products gained wide acceptance and the company made money; the profits being plowed back to reduce indebtedness. Close contact was kept with customers in the field by company officers, design engineers and field engineers. In 1929 the great depression struck but did not make itself felt to any great degree until 1931 when wheat dropped to 25 cents a bushel. Trading steel for 25 cent wheat was practically out of the question. The company had not been in business long enough to clear their debt and build a reserve fund to carry them through so the banking interests placed a manager in charge in late 1931. Under the bank manager a gradual liquidation policy was pursued. I am sure that this group of men would have gone forward successfully had they had enough time to gain financial independence. Nearly all the key men left to join another harvester company in similar capacities and they have made a success there these past twenty years. In 1938, with liquidation complete, two local businessmen purchased the parts manufacturing business for the required 10 year period. They changed the name to Avery Farm Machinery Co. Inc. In 1941 the large plant was sold to R. G. LeTourneau Inc. and the parts business was moved to smaller quarters on South Washington St. in Peoria. In 1949 the corporation was dissolved and, with considerable demand still existing for Avery parts, Mr. Earl K. Smith purchased the parts manufacturing rights. Mr. Smith changed the name to Avery Farm Machinery Co. and is today engaged in both the manufacture of Avery parts and a line of Hart Oil Burners. I might mention here that the Avery tractor currently being merchandised by Montgomery Ward and Co. is being built by the B. F. Avery Co. of Louisville, Kentucky and has no connection with the former Peoria Company. Yes, I think that if an engineering, research and training program had been a part of the old Avery Co. policy, David McCullough's prophecy of 1902 might have become a reality. Wouldn't he be amazed if he were here to witness the huge industrial expansion that has taken place in the Peoria of 1952?

Source:

www.phelpsfamilyhistory.com/branches/phelps/wataga/avery_tractor_company_history.asp

Avery trucks did better. The Avery Co. of Peoria, Ill., was well known for its steam engines and tractors, including the 8-16 and the 14-28. When the company ventured into the truck field in 1910, it was well situated in the agricultural field, with a dealer network in place to help let buyers know about the new product.

The Avery Co. described its motor truck as a "gasoline farm wagon" and "general farm power machine." The firm decided up front that its trucks would be most useful to farmers during the harvest season, so they included a large belt pulley that could be attached to the front crank shaft for powering grain separators and other belt-driven machines. Early Avery trucks also had cast steel wheels with holes into which wooden plugs could be driven, to give added traction; when the wood wore down, new wooden plugs were simply inserted.

Company advertising claimed the truck carried loads on its own body, pulled plows and other machinery in the field, and drove other machines by belt power: "You can do road work, field work or belt work, all with this one machine."

.jpg)

No comments:

Post a Comment